We do what is necessary to maintain quality.

Production planning

Increasing the speed of production, reducing waste and improving the quality of manufactured products is our most important desire. With the help of production planning, the use of resources is in its best condition. This helps us to ensure that in addition to the right price, the quality is at its highest level.

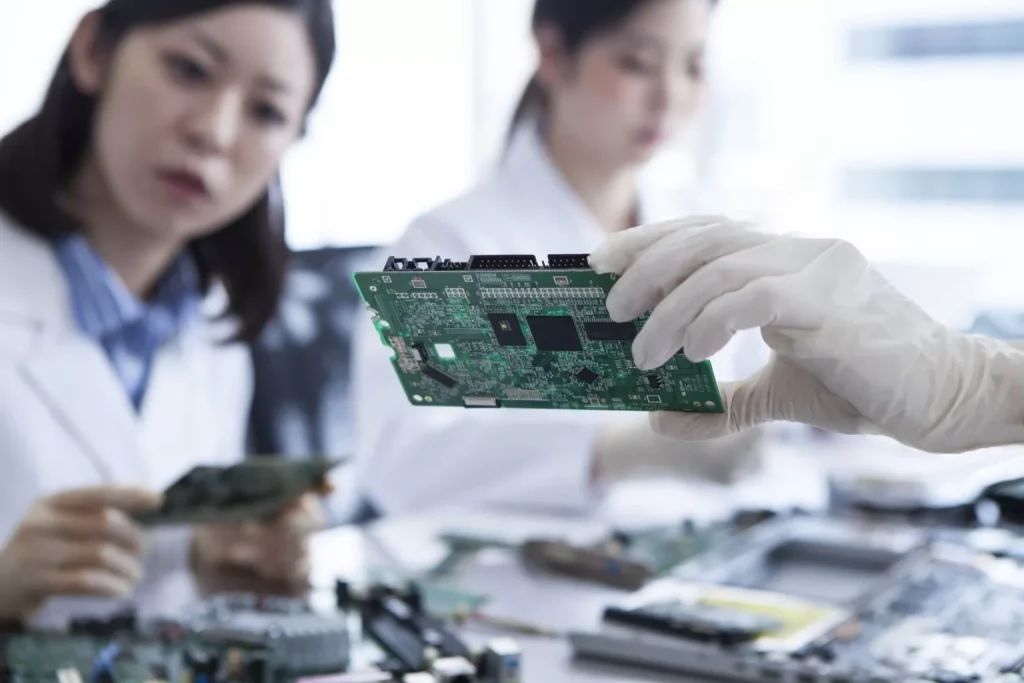

Quality control

Quality control is a continuous process in the production of electronic products, starting from the moment the components enter the production cycle (IQC), continuing throughout all stages of production (IPQC) and continuing until the end of product production (OQC). It is this continuous monitoring that has placed our manufactured products at the highest quality.

Quality assurance

In order to maintain product quality stability, all products, test and measurement tools, jig testers, etc. are periodically reviewed. For example, to evaluate manufactured products, a number of products are randomly removed from the production line and re-evaluated by an independent team.

Specialized warehousing of electronic components

Due to the various sensitivities in electronic components, it is necessary to pay attention to many details during storage. Some of these sensitivities include the lifespan of the components and the date of manufacture of the component, the temperature of the storage location, the permissible humidity level, and standard packaging, which makes the storage of electronic components a specialty.

Parts supply

To maintain the quality of our products, we source our parts from the most reputable domestic and foreign suppliers. The criteria for selecting these suppliers are, in addition to quality, reasonable price and speed in supplying parts.