How do we work?

Analysis phase

In this phase, while establishing close communication with the customer and the consumer market, the functional requirements of the product are obtained. By examining similar or similar Iranian and foreign products, as well as examining limitations and standards, the features of the final product will be extracted.

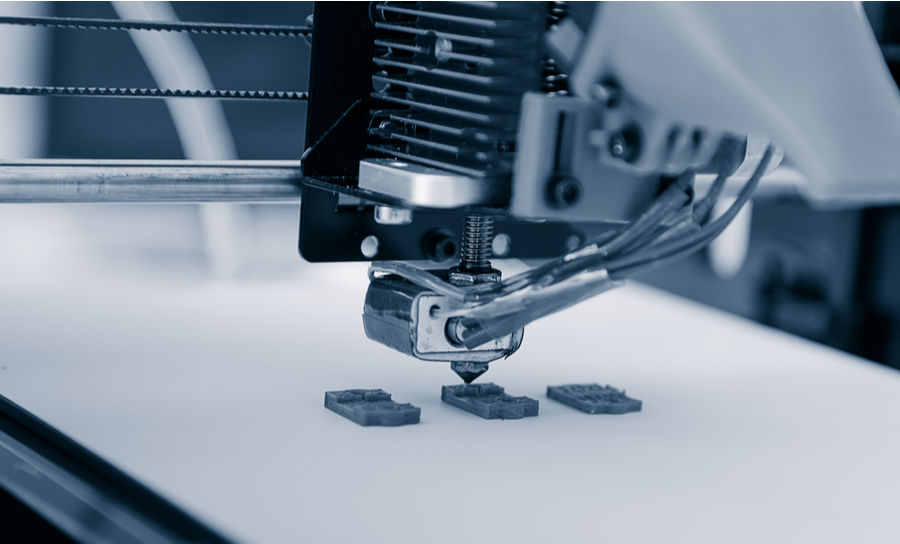

Prototyping phase

After the analysis phase and understanding of the product's limitations and requirements, a prototype of the product is built. In a way that all the customer's functional requirements are met. At this stage, the customer's feedback on the final product is provided. In this phase, modifications may be made to the final product based on the feedback received. Usually, 3D printing is used for the product form at this stage.

Pre-production phase

Entering the consumer market requires observing many points in meeting the conditions of consumption and application of the product. These conditions can be the result of environmental standards and consumption grades and appearance and quality control and production issues. Applying these requirements leads to the production of a quality product that can be used in the consumer market. In this phase, industrial molds are usually made and a limited number of products are produced.

Mass production phase

In this phase, while designing and building production equipment and infrastructure, quality control processes are extracted and documented. Finally, appropriate product packaging is designed according to customer needs.